Bitumen Quality Control & Laboratory Testing

At Black Gold, quality is not a checkpoint — it’s a continuous process. Our commitment to quality control ensures that every batch of bitumen leaving our facility is reliable, compliant, and engineered for peak performance, even under extreme climatic and load-bearing conditions.

With state-of-the-art laboratories, certified protocols, and a team of industry-trained chemists and engineers, we guarantee that our bitumen products not only meet — but exceed — international standards.

Our Quality Control Capabilities

Our in-house and partnered laboratories are equipped with advanced testing equipment that covers a wide spectrum of bitumen properties, including:

Core Bitumen Tests

- Penetration Test – Measures consistency and hardness

- Softening Point Test – Assesses thermal behavior

- Ductility Test – Indicates flexibility under stress

- Viscosity Test – Ensures pumpability and performance during application

- Flash & Fire Point – Verifies safety and handling conditions

Advanced Performance Grading

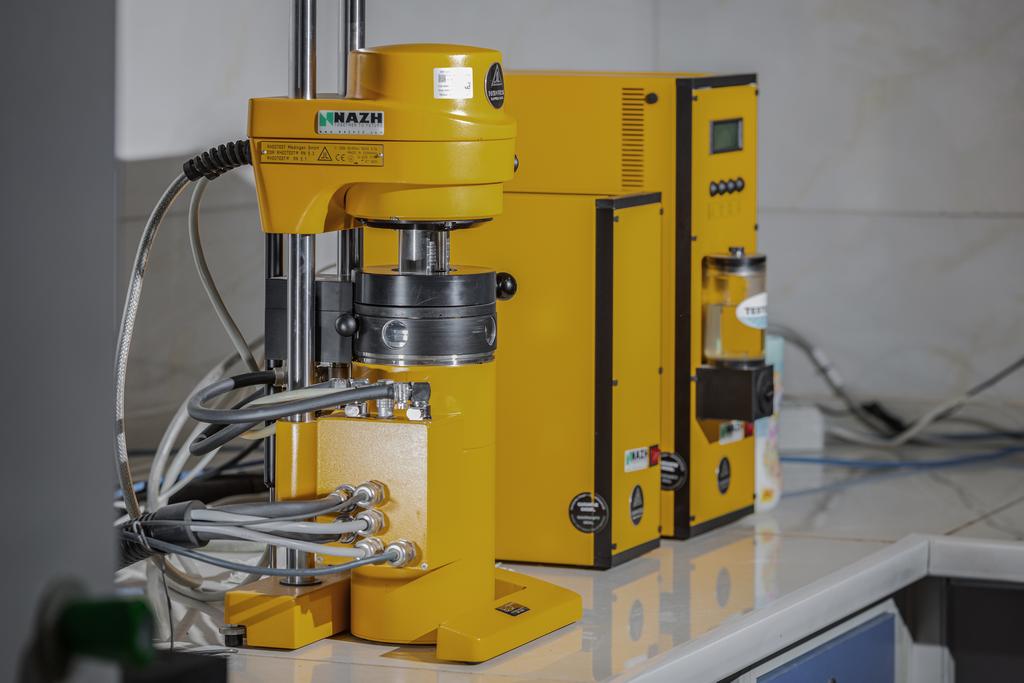

We utilize high-precision instruments including:

- Dynamic Shear Rheometer (DSR) – Evaluates rutting and fatigue resistance

- Bending Beam Rheometer (BBR) – Assesses low-temperature cracking potential

These instruments help us classify bitumen according to AASHTO M320 (PG grading) standards, ideal for performance-based specifications in high-value infrastructure projects.

Analytical & Purity Testing

In addition to performance-based parameters, we monitor chemical composition and purity using methods such as:

- Solubility Test – Confirms binder purity

- Spot Test – Detects impurities or unblended residues

- Ash Content Analysis – Ensures absence of non-bituminous residues

Certifications & Standards

Our laboratories and quality control processes operate under globally recognized certifications and protocols:

- ✅ ISO/IEC 17025 – Certified testing and calibration competence

- ✅ European CE Certification – Compliance with EU safety and performance standards

- ✅ ASTM, AASHTO, and EN Compliance – For penetration, viscosity, and PG-grade bitumen

- ✅ Standardized Environmental Conditions – Controlled temperature and humidity settings in lab environments

All testing procedures are traceable and audited periodically for reliability, repeatability, and regulatory alignment.

Lab Infrastructure & Equipment Highlights

- Automated Kinematic & Dynamic Viscosity Analyzers

- Penetrometers with climate-controlled test chambers

- Ring-and-Ball Apparatus for Softening Point

- Full Rheology Suite for Superpave Performance Testing

- Rotational Thin Film Oven (RTFO) & Pressure Aging Vessel (PAV) for simulating long-term aging

Our laboratories are calibrated to reflect real-world conditions, allowing engineers and specifiers to trust the performance data when planning complex infrastructure.

From Lab to Road: Why It Matters

Every property we test contributes to the performance longevity, safety, and cost-efficiency of your asphalt mix. Whether you’re building highways in desert heat, tunnels in alpine climates, or urban roads with heavy traffic loads, our lab-tested bitumen ensures stability, flexibility, and durability.

At Black Gold, your roads are built on science.