1- Penetration Test

The penetration test is a fundamental method for determining the hardness or softness of bitumen. This test classifies bitumen based on how deeply a standard needle penetrates its surface under specific conditions—typically with a 100-gram load applied for 5 seconds at 25°C.

The depth of penetration, measured in tenths of a millimeter (0.1 mm), indicates the consistency of the bitumen. Softer bitumen exhibits higher penetration values and greater ductility, making it ideal for colder climates where flexibility is critical. Conversely, harder bitumen with lower penetration is better suited for hot climates, offering improved resistance to deformation under high temperatures.

This test plays a key role in grading penetration bitumen directly from the refinery and is widely used in asphalt production to match bitumen performance to environmental conditions.

2- Viscosity Test

The viscosity test evaluates the flow characteristics and adhesion capability of bitumen to asphalt aggregates. Achieving the optimal viscosity is critical in road construction: if the bitumen is too viscous, it will not mix properly; if it’s too fluid, it won’t bind the aggregates effectively.

Viscosity is highly sensitive to temperature. As temperature increases, bitumen becomes less viscous and loses its cohesive strength. To ensure proper performance, viscosity is measured at two key temperatures: 60 °C (representing in-service road conditions) and 135 °C (representing mixing and compaction conditions). These measurements help determine the ideal temperature range for mixing bitumen with aggregates and for compacting the asphalt mix.

The test is conducted using a viscometer, which measures the time it takes for a specified amount of bitumen to flow through the device. This time is then multiplied by a device-specific correction factor to calculate the bitumen's viscosity.

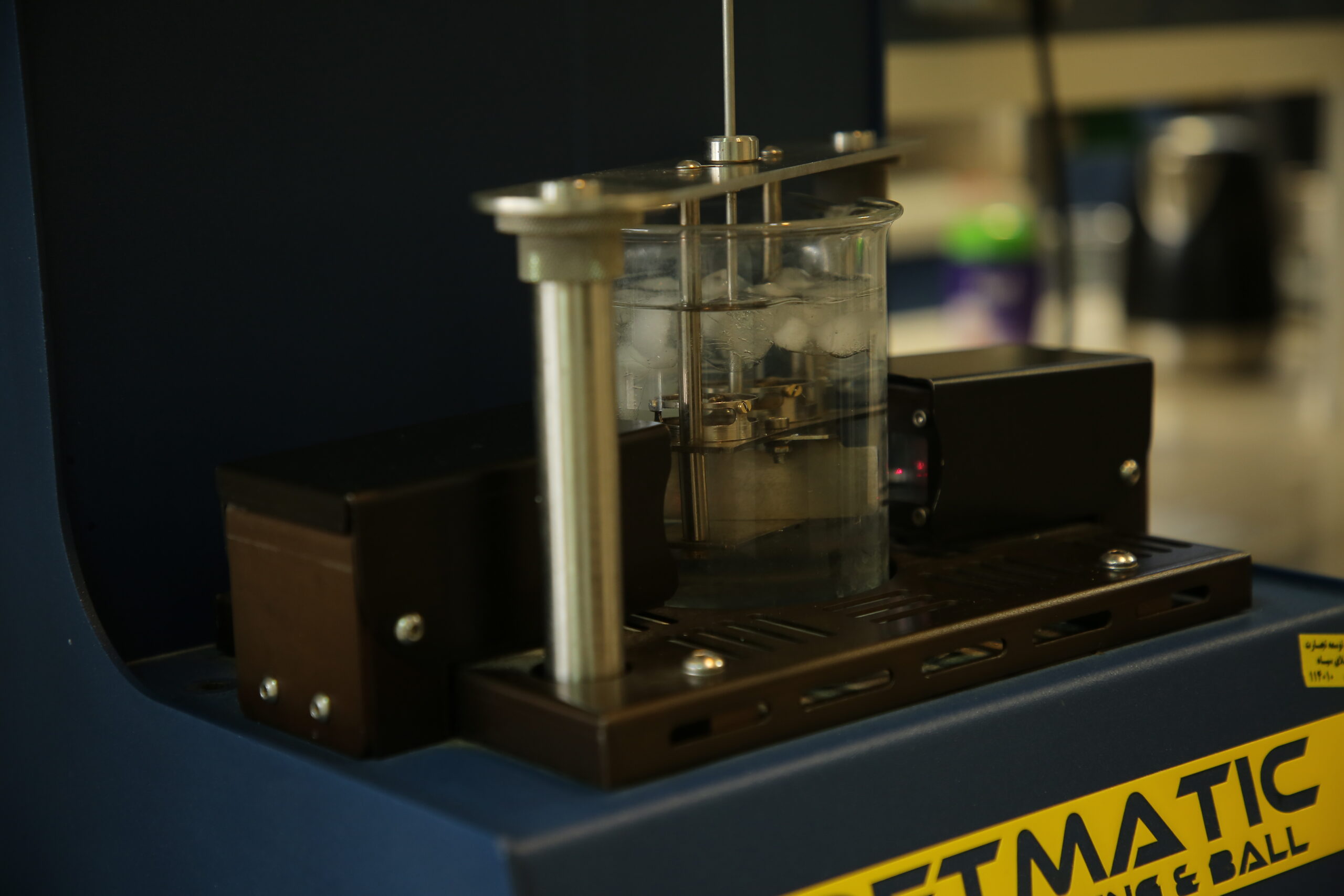

3- Softening Point Test

Bitumen, composed of various hydrocarbon fractions such as asphaltenes and resins, does not have a distinct melting point. Instead, it gradually softens when heated. The softening point is the temperature at which bitumen transitions from a semi-solid to a more fluid state, and it is a critical indicator for engineers assessing bitumen's performance under heat.

This temperature marks the point where bitumen begins to lose its cohesive strength and adhesive properties, making it especially important in climates with high surface temperatures.

The Ring and Ball method is the standard laboratory procedure for determining the softening point. In this test, two samples of bitumen are poured into brass rings, and a steel ball is placed on top of each sample. The setup is then immersed in a water bath and gradually heated.

The softening point is recorded as the temperature at which the bitumen-softened steel ball drops to the bottom of the beaker, indicating the bitumen has reached a specific level of flow.

4- Ductility Test

Ductility is a key indicator of bitumen’s ability to withstand deformation without breaking. Bitumen with high ductility is more resistant to the stresses caused by traffic loads and temperature-induced expansion and contraction, making the asphalt less prone to cracking and significantly extending its service life.

To measure ductility, a sample of bitumen is placed in a standard mold and then stretched at a constant speed of 5 cm per minute. The test continues until the bitumen strand breaks. The distance the sample stretches before rupture, measured in centimeters, is reported as its ductility.

A longer stretch indicates greater ductility, which translates to better flexibility and performance in real-world pavement conditions.

5- Specific Gravity Test

Specific gravity is defined as the ratio of the mass of bitumen to the mass of an equal volume of water. This property is unique to each type of bitumen and is useful for identifying impurities, verifying quality, and performing precise calculations in mix design.

The test is conducted using a pycnometer. The procedure involves:

Weighing the empty pycnometer.

Filling it with bitumen and recording the new weight.

Repeating the process with water.

By subtracting the weight of the empty pycnometer from the full readings, we obtain the net weights of the bitumen and water. The ratio of these two values gives the specific gravity of the bitumen.

This value is important in volume-weight conversions and ensures consistency in pavement material formulations.

6- Solubility in TCE

The solubility test is used to evaluate the purity of bitumen by detecting non-oil insoluble materials. These impurities—such as dust, mineral particles, or organic contaminants—can significantly reduce the adhesive strength of bitumen and compromise its performance in asphalt mixtures.

In this test, 2 grams of bitumen are dissolved in 125 ml of trichloroethylene. The solution is then passed through Whatman filter paper. The insoluble residue is thoroughly washed, dried, and weighed.

The percentage of impurities is calculated using the formula:

Insoluble Matter (%) = (Mass of Insoluble Material / Mass of Bitumen Sample) × 100

A high level of insoluble matter—above 1%—is considered a sign of low-quality bitumen and may lead to reduced cohesion and shorter pavement lifespan.

7- Flash and Fire Point Test

Due to the flammable nature of bitumen, understanding its thermal behavior is critical for safe transportation, storage, and handling. Two key safety indicators are the flash point and the fire point—both of which determine the temperatures at which bitumen vapors can ignite.

When bitumen is heated, it begins to release vapors. If these vapors come into contact with an ignition source, such as a flame, they may ignite. This is especially important in storage environments where high temperatures or open flames may be present.

Two standard apparatuses are used for measuring these points:

Pensky-Martens Closed Cup Tester

Cleveland Open Cup Tester

Test Procedure:

Bitumen is poured into the test cup and heated gradually. A flame is passed over the surface every 2 seconds during the heating process.

The flash point is the temperature at which a brief flame appears on the surface of the bitumen—indicating that vapor concentration is sufficient to ignite momentarily.

The fire point is reached when the flame sustains itself for a few seconds, signaling that the vapors are present in enough quantity to maintain combustion.

These values are crucial for setting safe operational and storage limits and ensuring compliance with safety regulations.

8- Loss on Heating Test

The Loss on Heating test measures the amount of volatile compounds present in bitumen. Volatiles are low-boiling-point substances that evaporate easily when heated. Their presence affects the durability and performance of bitumen during asphalt production and application.

A high volatile content causes the bitumen to harden during heating, reducing its elasticity and making it prone to cracking. For quality paving applications, the volatile content should be less than 1%.

Test Procedure:

A 50-gram bitumen sample is placed in an oven and heated at 163 °C for 5 hours.

After cooling, the sample is reweighed to determine the weight loss.

The percentage of volatile loss is calculated using the formula:

Loss on Heating (%) = [(Initial Weight – Final Weight) / Initial Weight] × 100

This test is essential for ensuring the bitumen retains its flexibility and binding properties during asphalt mixing and compaction.

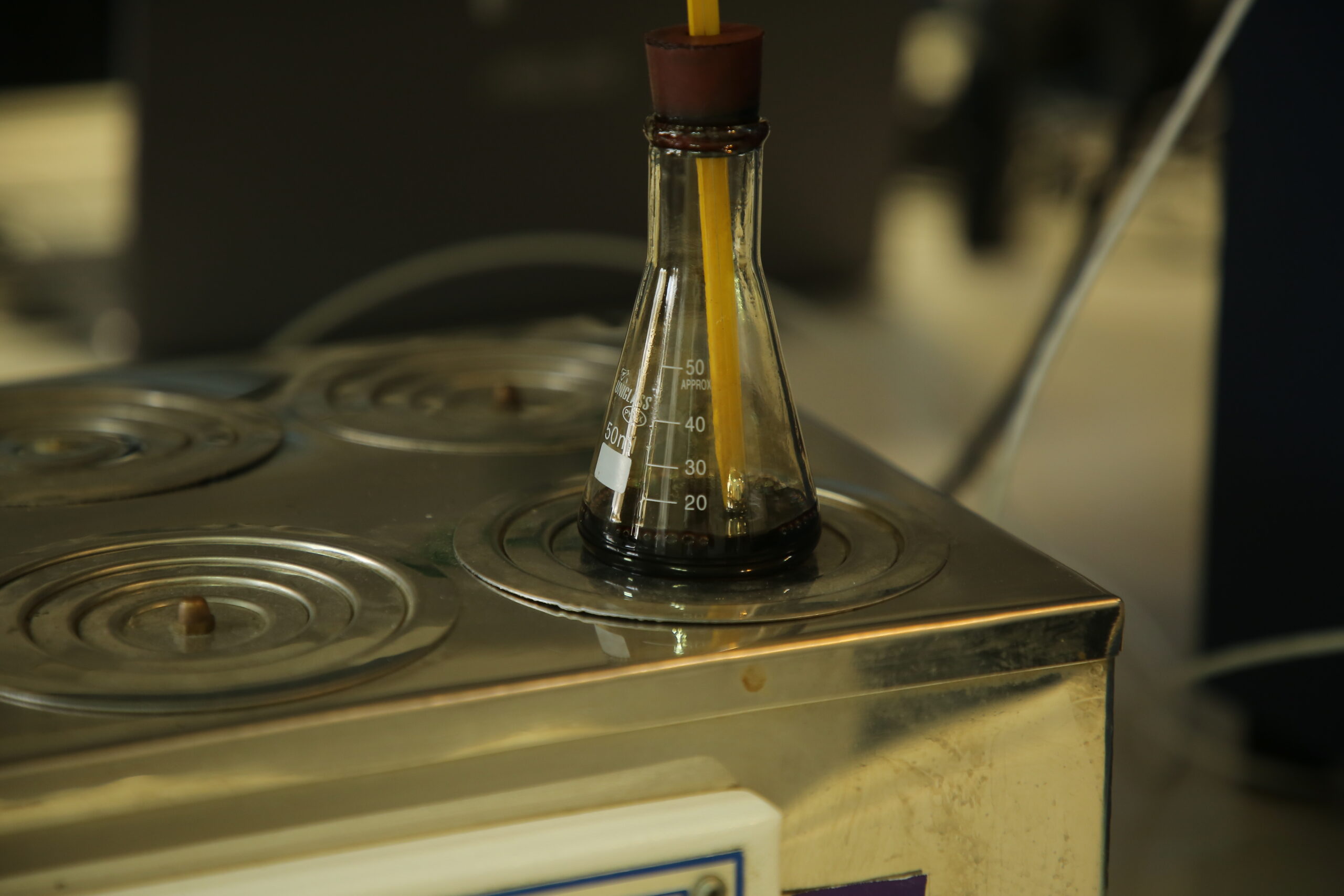

9- Spot Test of Bitumen

The spot test is used to detect whether bitumen has been thermally damaged during the refining process. Overheating bitumen in a refinery can cause thermal cracking, leading to chemical degradation. Cracked bitumen loses its adhesive strength, making it unsuitable for binding aggregates or withstanding the high temperatures used in road construction.

Test Procedure:

2 grams of bitumen are placed in a flask with 10 ml of solvent.

The mixture is rotated and heated in boiling water until the bitumen fully dissolves.

Once the solution cools to room temperature, a drop is placed on filter paper.

Result Interpretation:

If the spot is uniformly brown, the test is negative, indicating the bitumen is sound.

If the spot has a black center surrounded by a brown ring, the test is positive, showing the bitumen has been damaged by overheating.

This quick visual test is essential for identifying unsuitable batches of bitumen before use in asphalt production.

10- Drop in Penetration after Heating Test of Bitumen

The Drop in Penetration test is used to evaluate how much a bitumen sample hardens after being subjected to heat, primarily due to the evaporation of volatile components. As bitumen loses volatiles during the heating process, it becomes harder, which can affect its flexibility and performance in asphalt applications.

This test indirectly measures the volatile content and hardening susceptibility of bitumen.

Test Procedure:

Perform a standard penetration test on the original bitumen sample using a 100-gram load applied for 5 seconds. Record the penetration depth in tenths of a millimeter (0.1 mm).

Heat the sample in an oven at 163 °C for 5 hours.

Allow the sample to cool to room temperature.

Repeat the penetration test on the heated sample under the same conditions.

Calculation:

Drop in Penetration (%) = [(Initial Penetration – Final Penetration) / Initial Penetration] × 100

A high drop in penetration percentage indicates greater hardening due to volatile loss, which may affect the bitumen’s suitability for specific climate or traffic conditions.