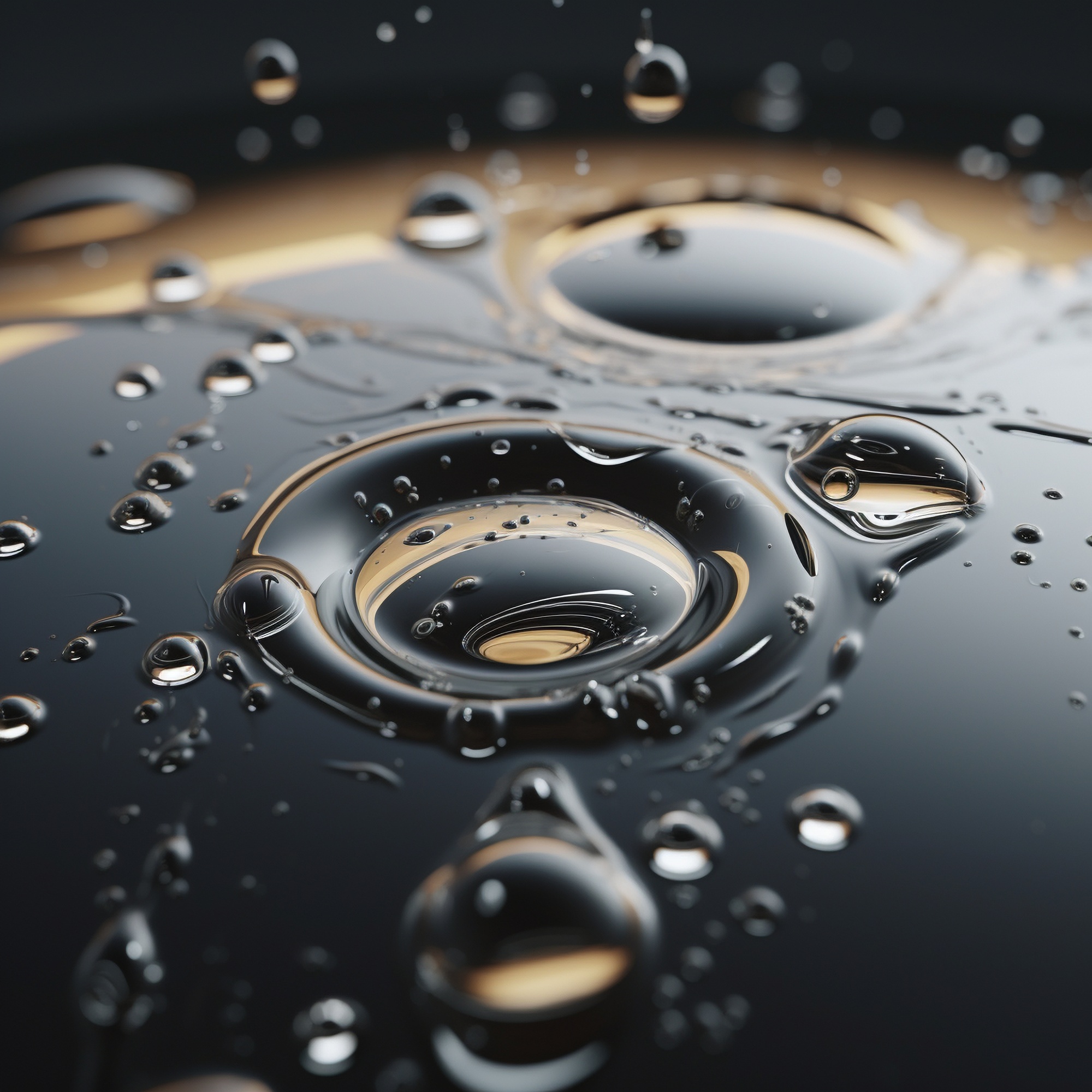

Emulsion

Bitumen emulsion is a liquefied type of bitumen with a low viscosity.

By dispersing bitumen in water and adding an emulsifier, ordinary bitumen turns into a low viscosity liquid that can easily be used in a variety of applications, including repairing and maintaining roads, waterproofing, spraying, etc.

Emulsions make it easy to handle, store, transport, and apply bitumen at a lower temperature.

Since this type of bitumen is liquid, there is no need to heat it before application.

Moreover, applying bitumen emulsions using cold techniques reduces energy consumption and makes road construction environmentally friendlier.

What is Bitumen Emulsion Composition?

Bitumen emulsion is a combination of water and bitumen.

As the mixture of water and oily products quickly separate, a third component, known as emulsifier, is normally added to the mixture in order to make it more stable.

Generally speaking, the amount of bitumen in the bitumen emulsion is 55 to 65%, the amount of water 35 to 45 %, and the amount of emulsifiers should be a maximum 0.5% of bitumen emulsion’s weight.

Emulsifiers are used for making a mixture of water and oil dispersed in each other.

In addition to their ability to reduce the tension between oil and water molecules, emulsifiers have an electronic charge that affects the molecules of bitumen emulsion and leads to categorizing it into Cationic and Anionic.

Cationic emulsifiers, for example, form a layer of positive charge around the bitumen droplets that prevent them from joining each other.

This makes bitumen dispersion in water more durable.

The electronic charge of bitumen emulsion decides on what kind of surface it should be used.

Some aggregates (such as marble aggregates) mix well with anionic bitumen emulsion and some others are a better solution to cationic bitumen emulsion (such as granite aggregates).

How is Bitumen Emulsion Manufactured?

Bitumen emulsion is usually made using a colloid mill, which mixes bitumen with water and emulsifier. In this process, bitumen is milled into very small droplets that can easily suspend in the water.

With the addition of emulsifiers, bitumen droplets become more water friendly. Water droplets also move closer to the tiny bitumen droplets, ensuring that the final bituminous product is stable enough.

In the manufacturing process, many factors such as droplets’ size, chemical addition, and the temperature of various components are accurately controlled.

The resulting bitumen has a consistent structure that makes it unique for various applications.

Different Types of Bitumen Emulsion

Various emulsions are classified based on two main factors:

- particles’ electrostatic charge

- breaking or setting time

In an emulsion, if the particles’ charge is negative, the bitumen emulsion is called Anionic and introduces itself with the letter “A”. Otherwise, the bitumen is known as cationic and has the “C” letter.

The second grading system of bitumen emulsion is closely related to the application. When applied to a surface, bitumen emulsion must break and set.

Technically, breaking means the evaporation of water, which makes bitumen strong enough for sticking to aggregates and setting on the place of application.

The time that is needed for bitumen emulsion to lose water and behave like an ordinary bitumen, is called the reactivity rate.

This parameter determines whether the bitumen is rapid setting emulsion, medium setting emulsion, and slow setting emulsion.

When bitumen emulsion is applied to a surface, choosing the right setting type is crucial. As previously said, there exist three types of the bitumen based on the setting time.

The first one is rapid setting emulsion which sets quickly in contact with aggregates; therefore, it is highly used in low surface of roads, particularly chip seals and surface dressing.

The second type is medium setting emulsion which is used in premixing of bitumen emulsion and coarse aggregate, particularly open graded mixes.

The last one is slow setting emulsion which sets very slowly. That’s why it is suitable for being mixed with aggregates of high surface area.

Slow setting emulsion is the most stable type of emulsion and can be used in dense graded aggregate bases, slurry seals, and recycling asphalt.

Another factor that can affect the reactivity of bitumen emulsion is the temperature of the surface onto which it is applied.

In hot weather, evaporation of water can accelerate.

Both cationic and anionic bitumen emulsions are categorized according to the setting time.

Look at the table below to find the various categories of bitumen emulsion and their globally standard names.